A production powerhouse for US Navy radars

Raytheon’s Radar Development Facility: Delivering fast, smart and at scale

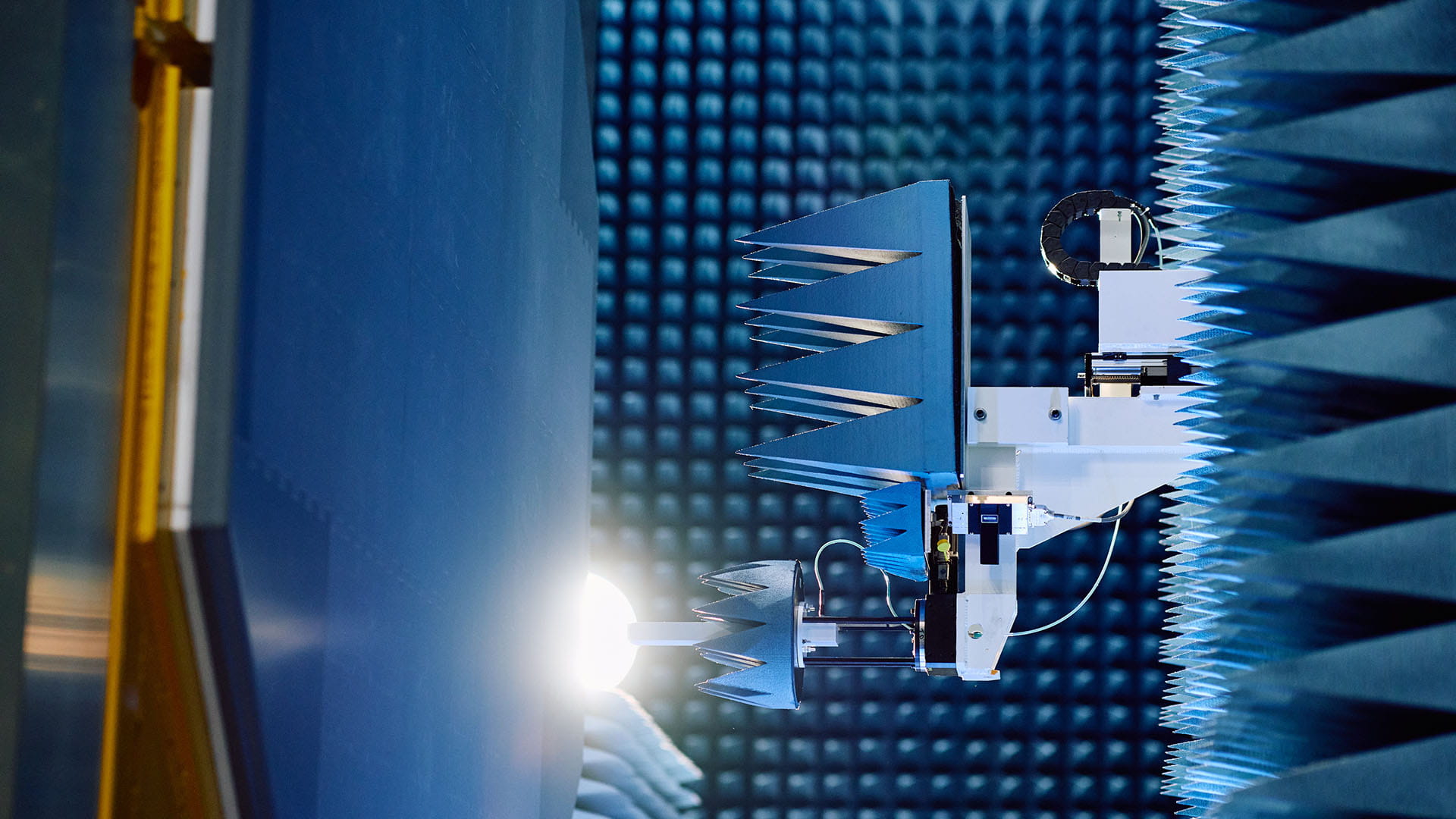

Just down the road, in a testing chamber with high ceilings and blue acoustic foam lining the walls, another chip just like it – nested inside a circuit card, then a larger assembly and ultimately a fully built naval radar – has a surge of power sent through it. A robot tests, torques and calibrates every part to make sure it’s ready to hit the high seas.

From there, it’s ready to ship out.

That end-to-end activity is the hallmark of what Raytheon calls its “vertically integrated” Radar Development Facility – and the very reason that the business, now several years into the design and manufacture of the U.S. Navy’s SPY-6 radar, is confident it can continue to produce that system on time, at scale and at reasonable cost.

“From chip to ship, every stage of production happens in parallel,” said Jason Rathbone, executive director of Naval Radars at Raytheon, an RTX business.

Built for the Navy’s needs

Every choice that went into designing the Radar Development Facility had the same goal: To produce the Navy’s powerful SPY-6 radar quickly, efficiently and reliably. SPY-6 is a family of advanced naval radars that allows ships to simultaneously detect and counter a host of threats in the air and at sea.

Integrated defense

Flexible deployment

Strategic edge

Bringing SPY-6 to life

How it all started

For ages, the U.S. Navy’s mechanical analog radars have tracked threats at sea. But those threats are becoming faster, more varied and far greater in number. That demands something more – a radar that can take on multiple missions at once.

To make the leap, the Navy shifted to a circuit card-based digital design. That, in turn, called for a complete transformation in how Raytheon built radars. Not only did the business have to innovate – it had to do so at scale, with unprecedented efficiency and precision.

“We recognized that we were entering a space where manual assembly and test no longer made sense. Although you can physically do it, it’s not possible at volume with the level of quality and repeatability required in our business,” Rathbone said.

That new mindset drove Raytheon to rethink everything, from manufacturing processes to testing protocols. All those changes needed a home. They found it in the Radar Development Facility, said Casey Looby, the SPY-6 production director at Raytheon.

Construction of the facility expanded the team's focus from building radars to finding better ways to do it.

Before transformation

- Mechanical analog radars with fixed capability and a single mission

- Manual processes and work areas specific to a single product

After transformation

- Circuit-card-based digital radars that scale to many types of missions and can perform them simultaneously

- Automated processes and work areas that can be used for multiple products

The SPY-6 radar’s production success is driven by its smart design, using shared components and technologies to streamline manufacturing.

“Part of the power of the SPY-6 design and the family of radars is the high volume of commonality – commonality in piece parts, commonality in technology,” Looby said.

SPY-6 has four variants that are made from the same parts and have the same core capabilities. The difference is in their size, arrangement and software programming, which can be modified to fit the needs and requirements of the ships they protect.

“Being able to develop and build in the same place has made a huge difference in how quickly we can scale,” said Sarah Jennette, an RTX transformation expert who led expansion of the modern radar hub. “The vision was always to make it scalable – to create a space where we could grow without being constrained by physical parameters.”

The rigorous effort put into production is mirrored in the testing process. Raytheon’s approach relies on incremental testing that begins at the chip level in the GaN foundry, continues through circuit card manufacturing and extends into array assembly.

“Depends on the product, but there are hundreds of hours of tests on most items as we walk through the whole product journey in the factory,” Rathbone said.

To ensure quality at every stage, Raytheon uses advanced tracking tools like digital thread technology, including Radio Frequency Identification and Unique Identifier codes. These tools scan parts at each stage, tracking precisely where they came from and the steps they go through.

Once components are assembled into their respective structure, an automated guided vehicle moves the array into one of the Radar Development Facility’s two near-field ranges for testing and calibration.

“By the time an array leaves Raytheon, we’re confident it meets mission requirements,” Rathbone said. “It’s ready to bolt onto a Navy ship and operate – no further testing needed.”

Equipping the fleet

The U.S. Navy is putting the SPY-6 radar on all its destroyers, frigates, carriers and amphibious ships.

“Our customer likes to say we are ‘invading the fleet with SPY-6,’” Rathbone said, recalling a conversation with a U.S. Navy captain. “And he couldn’t be more right.”

Raytheon has delivered more than 15 SPY-6 radars to the U.S. Navy, and in all, the SPY-6 family is set for deployment on more than 60 U.S. Navy ships over the next decade.

“Once SPY-6 is deployed across the fleet, I think sailors will provide feedback that unlocks new capabilities we haven’t even imagined yet. I truly believe that,” Rathbone said.

Raytheon’s suite of maritime sensors and precision weapons

Learn MoreWhat’s next

Raytheon is building on its SPY-6 experience to develop proposals for future radar systems – those designed for many tasks such as tracking ships, spotting submarines and resisting electronic jamming.

“At the end of the day, it’s just energy. It’s RF energy controlled by software,” Rathbone said. “Sky’s the limit in terms of what we can do with that energy.”

And make no mistake – they fully intend to find out.

“We’re just scratching the surface in terms of the opportunities that this technology will enable as we take a different mindset or perspective on what a radar truly is,” he said.

.jpg?rev=73a7970fa9f44a8fa8c8363aad05a991&rid=3c10bf193cd441d78c26f722a4c0dd72)