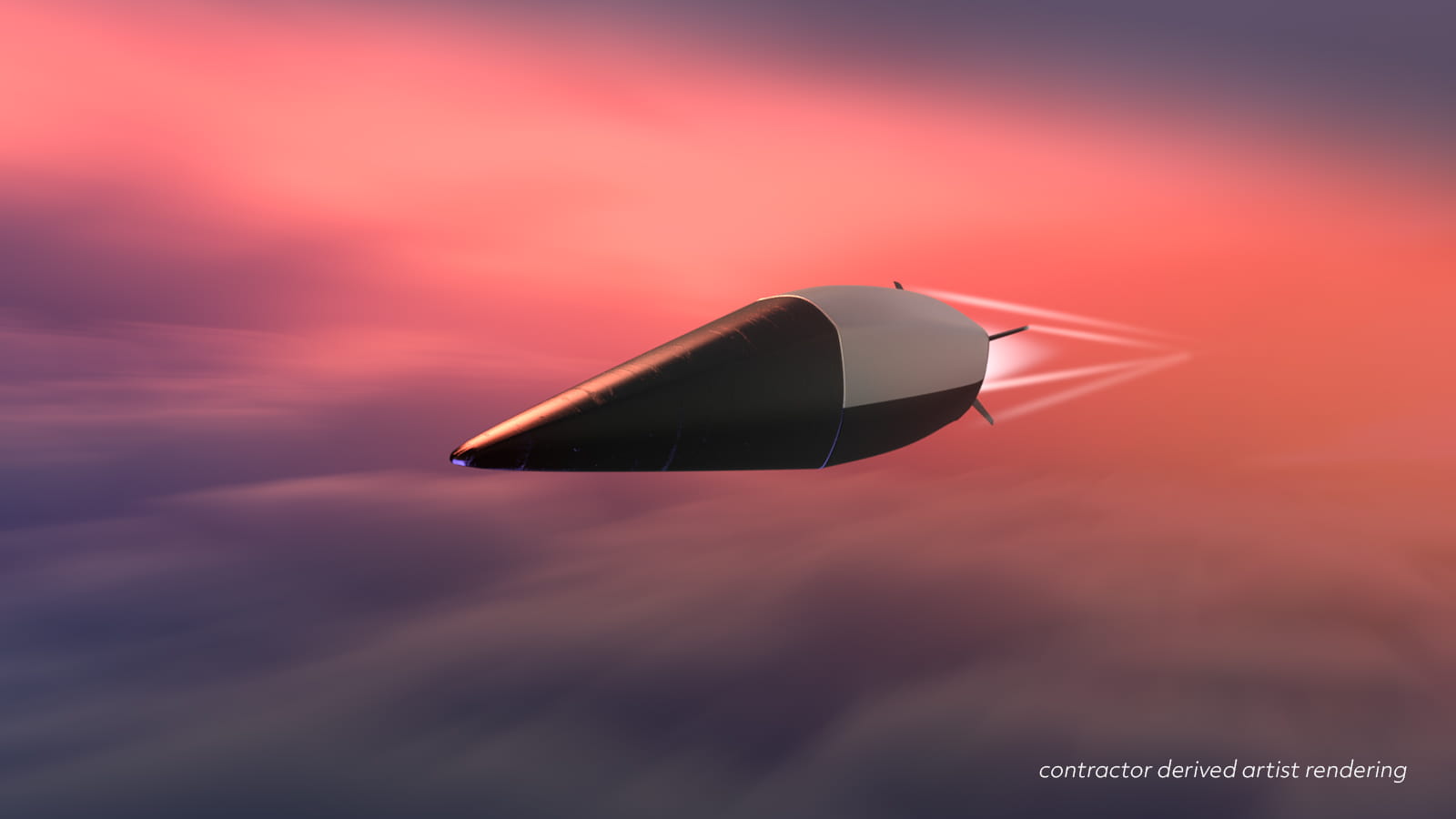

Air-breathing hypersonic weapon delivers value and performance

Two core technologies are at the heart of the U.S. pursuit of hypersonic weapons, or those that travel Mach 5 or faster: scramjets, which derive propulsion from the air around them, and boost-glide systems, which use a rocket motor to reach the edge of space and then descend to their target.

Raytheon, a Raytheon Technologies business, and Northrop Grumman are making significant investments in scramjets. Here are some of the reasons that approach holds particular promise.

We’ve already tested it successfully.

The air-breathing scramjet relies on high speed to operate. After being boosted, air and hydrocarbon fuel are burned to produce thrust for sustained flight into the upper reaches of the atmosphere.

In 2021, the business, in partnership with the U.S. Defense Advanced Research Projects Agency, U.S. Air Force and Northrop Grumman, successfully completed the first flight test of a scramjet-powered Hypersonic Air-breathing Weapon Concept, or HAWC, Missile.

“The HAWC flight test success was important because it demonstrated how far and fast the government-industry team has matured affordable scramjet technology,” said Wes Kremer, president of Raytheon.

It’s less expensive to manage heat.

One of the biggest challenges with developing hypersonic technologies is thermal management. Hypersonic systems heat up as they accelerate, so the business developed cost-effective solutions to protect the electronics from blazing temperatures without adding extra weight, which can reduce range.

Air-breathing systems can rely on low-cost conventional metals, such as nickel-based alloys, for their airframe. Nickel-based alloys are known for their corrosion resistance and strength and have superior durability to heat.

“Heat is still a factor for air-breathers, but these systems are much less reliant on exotic materials than other hypersonic systems, and that helps lower the cost significantly because traditional metals are easier to source and can be purchased in larger quantities,” Kremer said.

Scramjets can be produced efficiently.

Scramjet-powered hypersonics are designed and built leveraging the digital thread and additive manufacturing, or 3D printing.

“Digital design coupled with additive manufacturing is key to making air- breathing hypersonic weapons affordable,” Kremer said.

They can be integrated onto multiple aircraft.

Scramjet systems are smaller and can be installed on both fighter jets and bombers.

Air-breathing systems use hydrocarbon fuels that have high energy density, and because these systems use air from the atmosphere, they don’t need to dedicate space and weight to onboard oxidizers for combustion.

“Scramjet solutions can be carried in greater quantities because of their smaller size, which means they can be employed against more targets in a single mission. That’s a huge advantage,” Kremer said.

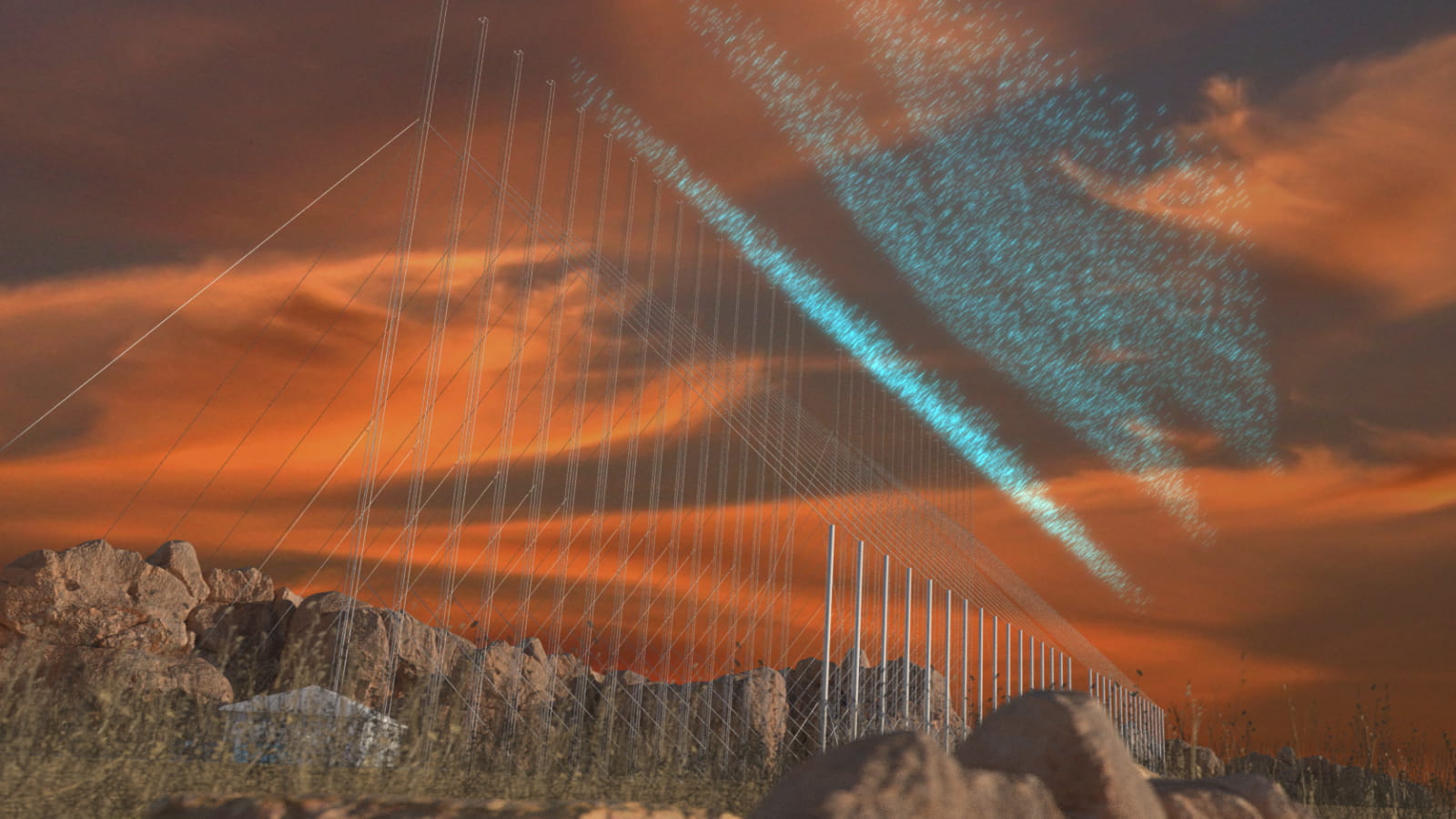

They’re survivable.

Hypersonic weapons – both air-breathing scramjet and boost-glide – offer increased survivability against advanced threats compared to legacy systems, allowing them to reach their targets. The altitudes they fly and their range and maneuverability make them difficult to detect and track.

“Air-launched weapons combined with Raytheon sensors provide incredible accuracy with inherent survivability, which equates to increased effectiveness over conventional systems,” Kremer said.