This lab has the power to make electrified flight a reality

The Grid, Collins Aerospace’s first-of-its-kind facility, prepares to test new technologies

On a table at a bright, new lab in Rockford, Illinois, a stream of electrons begins its journey.

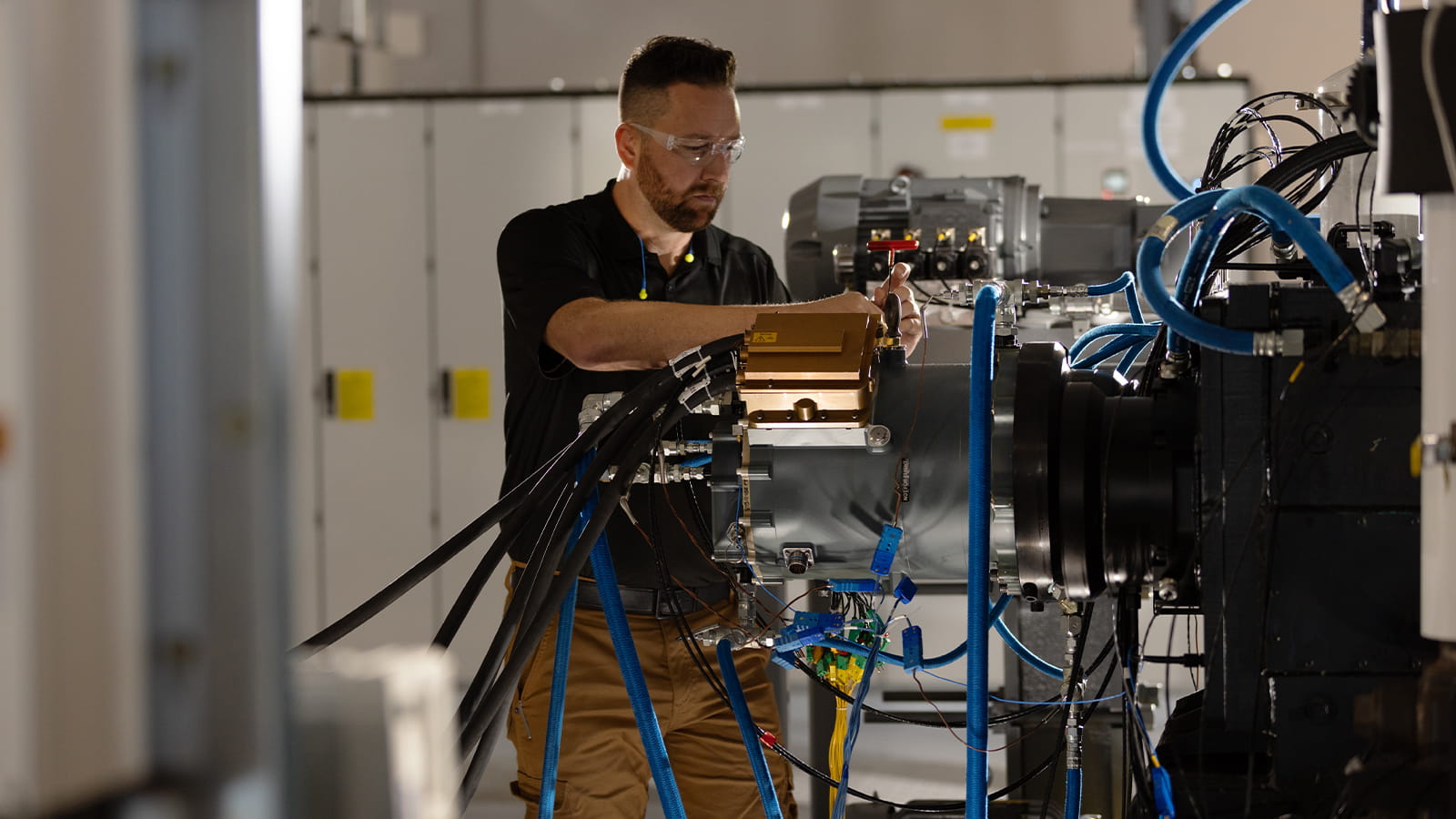

That journey starts with a device called a dynamometer, which spins a generator. In milliseconds, the electrons travel through a neatly tied bundle of cables. From there, they flow into a rectifier, a black box that will change the way they move — from back-and-forth (alternating current) to one direction (direct current).

This simple but important test will show whether the rectifier – small enough to fit in a backpack – can function at the voltage necessary for a hybrid electric unmanned aerial vehicle. That, in turn, will provide foundational knowledge for a larger effort to bring hybrid electric propulsion to single-aisle aircraft.

The test is one of many taking place at The Grid, an advanced electric power systems lab run by Collins Aerospace, an RTX business. The lab will allow Collins to develop electric motors, controllers, generators and distribution systems to achieve electrified propulsion on aircraft of all sizes. The effort to electrify propulsion is part of an industrywide goal to reduce carbon emissions.

This setup will help The Grid test power quality for unmanned aerial vehicles and prepare the lab for larger systems in the future.

Collins opened The Grid at its longstanding Rockford location in October 2023 to provide the space, power supply and modular design to test everything from a rectifier to a full engine – and how those pieces work together.

While most of the company’s test labs are meant for specific projects, The Grid is set up to build and test many new technologies quickly.

“The systems and the architectures that the lab represents are ones that haven’t been flown before,” Tyler Hayes, Collins’ discipline chief for propulsion electrification and hybrid systems said, “so we hope to figure out what’s possible for this new technology.”

What The Grid can do

The Grid’s 25,000 square-foot layout gives it two advantages: the ability to test full systems rather than individual parts, and the flexibility to do it in their real-world configuration.

“If you can imagine the distance from where you’re sitting on a plane by the wing all the way out to the engine, it’s a long distance,” Hayes said. “This lab has plenty of room to stretch out long cables, install them in the lab and actually give you a true representation.”

At each corner of the lab, there’s equipment for a setup like the one they are currently using to test UAV systems and mature The Grid. The lab can have up to eight dynamometers with each serving as a starting block for a project. The dynamometers act as an engine as they spin, and, from there, researchers can add on a piece at a time to create subsystems that they can validate as they build.

The Grid’s lab floor is as long as a football field is wide, which gives researchers room to test full systems in their real-world configuration.

The lab can also combine multiple setups to mimic multiple engines on an aircraft and pair them with software to simulate a flight from takeoff to landing.

“We can do all those things to test the full flight of the products,” Jared Schneider, a Collins chief engineer in propulsion electrification said, “and then the next step is what happens if something goes wrong? We can introduce faults, see how it behaves and prevent it.”

Powering The Grid

The Grid has 8 megawatts of electricity and the capacity for up to 15. That’s plenty of power, but it’s also supplied in a new way. The lab has its own substation from the local utility, which helps ensure a reliable source of power at adequate voltage.

Collins is building its first solar array there, too, which will provide clean electricity for The Grid and other labs and offices at the Rockford location. The Grid's load bank, a component used to absorb power during tests, was also designed with sustainability in mind. Rather than wasting excess electricity as heat, the bank can send it to the utility’s main grid to be used by homes and businesses nearby.

Additionally, the lab can emulate up to 4 megawatts of battery storage to test how battery systems will work on aircraft.

“We’re setting the bar for what a lab testing electrified powertrains should be. There’s really nowhere else you can do this easily right now,” Hayes said. “The Grid is a critical piece to the whole puzzle of trying to put these systems together and test them in a way that makes it look and feel like the aircraft.”

15

8

4

Megawatts of battery storage emulation

What’s next for The Grid

In a control room next to the lab, a team is working on an important piece of that puzzle: software.

The Grid can collect up to 2 million data points per second during a test, and as the rectifier’s power quality test runs next door, that data shows on control room screens as wavy lines whose peaks and valleys give the team valuable information.

“There’s a lot to learn,” Hayes said. “The peaks and valleys and how there’s some maybe fuzziness to the signals all goes into how we tune the controls of the rectifier software and the filtering of the hardware.”

The software they’re refining allows them to record test data and remotely operate equipment in the lab with just a few clicks. That seems simple, principal engineer Scott Barker said, but one click handles several layers of logic and getting it right requires hundreds of small tests. They’re designing the software to be as modular as the lab itself so that, when complete, its logic can be reused for other projects to reduce the time it takes to set up.

Tyler Hayes monitors The Grid from its control room, which has powerful processing capability to test components in detail.

The team is preparing for several new projects including SWITCH, a program for the European Union’s Clean Aviation Joint Undertaking where Collins, Pratt & Whitney and other partners are developing hybrid electric and water-injected turbofan technology to reduce fuel burn and carbon emissions.

“What SWITCH does,” Hayes said, “is take a single-aisle-size aircraft and says, ‘How can we make the engine more efficient and better integrate things into the aircraft to provide fuel-burn savings through a hybrid engine that’s more like something you would have in a hybrid car?’”

Pratt & Whitney will provide a hybrid-electric-ready GTF engine while Collins will provide megawatt-class electric machines and power electronics, high-voltage DC distribution and protection, thermal management components and nacelle architectures for the system.

The Grid will help test how the pieces will work together. Instead of the six to nine months required to set up a new project in The Grid today, the modular components they’re building will help reduce that to roughly two months.

“Every time we’re in The Grid, we’re building the lab to be prepared for a big program like SWITCH,” Hayes said. “We’re built for expansion. That’s the key – it really is an industry-leading facility.”